Xin chúc mừng, bạn đã đăng ký thành công

THACO BUS Plant is positioned as the largest bus manufacturing plant in Southeast Asia. It features automated and intelligent production lines integrated with green spaces inside and outside, producing a diverse range of THACO and international bus models, catering to both domestic and export markets.

| Established: | December, 2012 |

| Total area: | 17 ha |

| Annual output: | 20,000 vehicles |

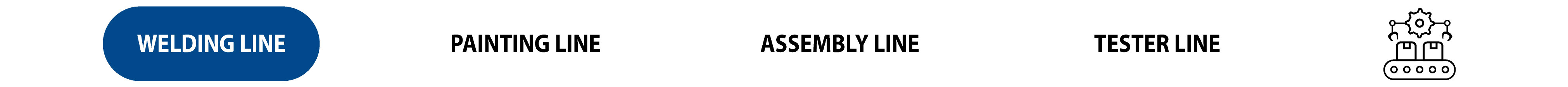

Welding line: Equipped with chassis production line and robotic welding system, combined with laser cutting technology for sheet steel and box steel, ensuring seamless production from parts to bodies.

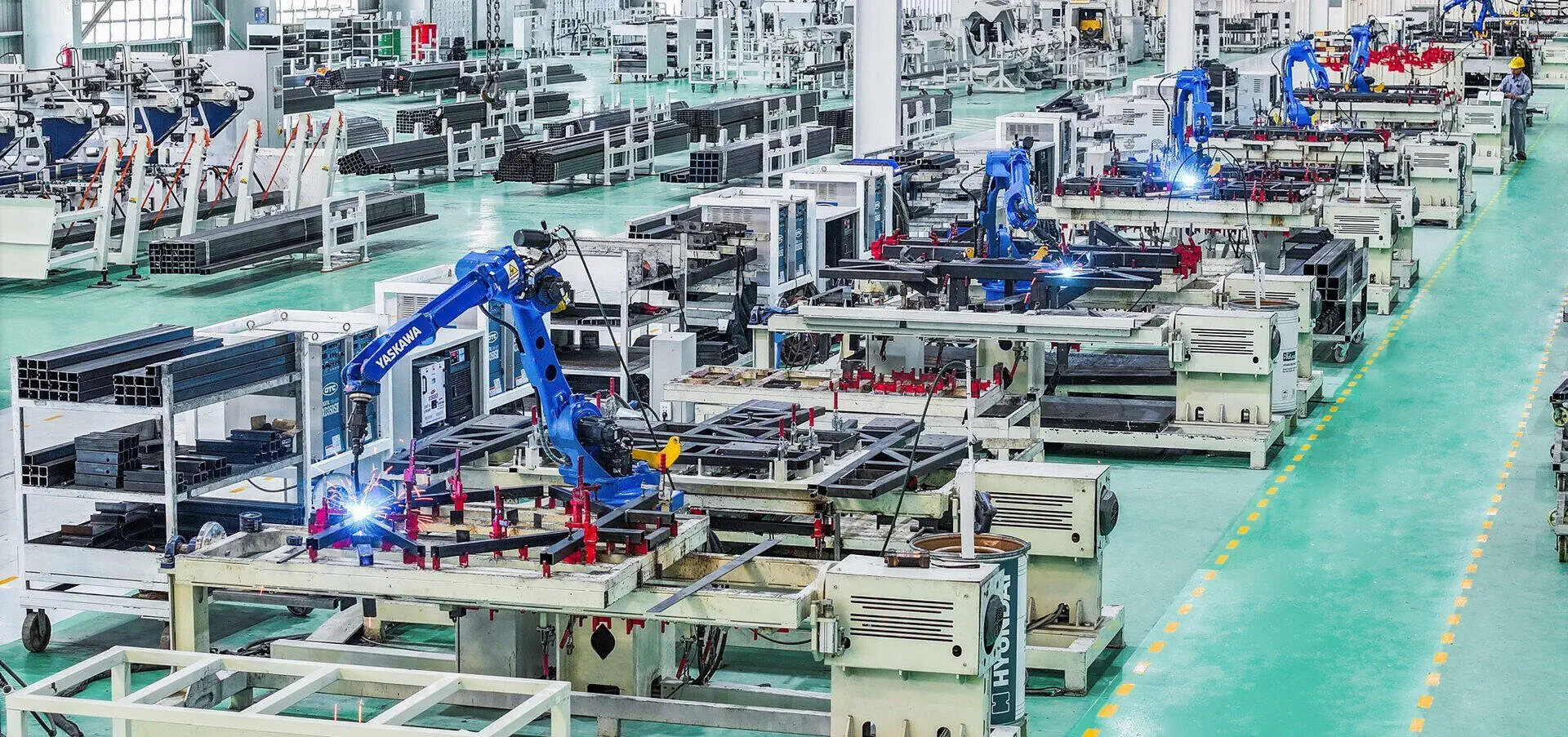

The ED line at the paint shop is one of the largest in Southeast Asia, offering 10 dip tanks that can dip an entire body up to 13.7 meters long. It applies the liquid shaping technology, zinc-based, with high penetrability and adhesion to produce a smooth, uniform surface that is corrosion-resistant under environmental conditions. The base coat line utilizes the 2K painting technology as the Japanese standard, meeting customers’ requirements for the painting color.

Integrated with an interior component manufacturing line to ensure synchronization, flexibility, convenience, and cost optimization.

The fully assembled buses will be under inspection for the headlights, steering angle, and brakes and testing on a 2.4km road which simulates various types of terrain. For international brand vehicles, the inspection process is conducted through an online-connected quality control system, ensuring the highest quality standards.

Giấy CNĐKDN: 4001221658 © 2021 THACO AUTO. All right reserved.